Fast Track to first oil – RAM analyses

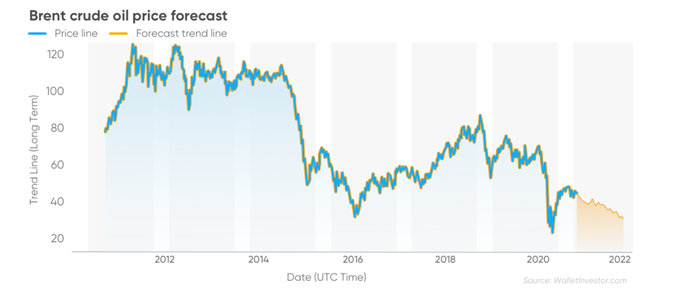

There is a lot of emphasis on getting to first oil / gas as soon as possible and this puts pressure on the select / define process (Pre-FEED / FEED stages) both in terms of timescales and cost.

However, this is potentially at the expense of analyses (in our case RAM studies) that can ultimately define the overall lifecycle cost for the asset.

RAM studies have come out top of the list in our recent poll on LinkedIn, where a question of ‘When going through Detail Design Project stage, which part of your Asset Management requires earliest attention?’ was posed.

In the short term, the design might satisfy the immediate requirements, but the eventual operator might have to live with difficulties over the entire lifecycle in areas such as supportability, operability and maintainability.

So as usual: money invested early on will reap many benefits over the longer term to the operator and this applies across the industries, not only Oil and Gas.

Often there are different contractors involved at the different stages through to the detailed design and award of EPC. In each case, price for the conduct of these stages will be a factor in the design competition. Therefore, there is a temptation to avoid what are perceived to be unnecessary analyses’ in favour of the standard or business as usual approaches.

We would consider that detailed Reliability Availability Maintainability (RAM) modelling, Asset Lifecycle Assessment and Strategic Asset Management Plan, Maintenance Budget Development and Obsolescence management are an integral and necessary part of all of those early stages and not an optional extra or “nice to have”.

This is often left to the Execute / Operate phase by which time it is perhaps too late, when carried out at those later stages the model is of “as is”, rather than “should be” and thus misses playing a contributing role in the design process.

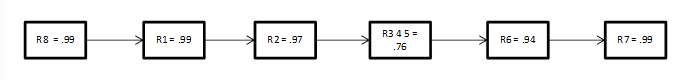

When availability modelling is included during the early stages, it is often limited to simple excel sheet approaches, based around simple Reliability Block Diagrams (RBDs), this is simply to confirm in principle that the design meets any target operational availability requirements (if given). This often just considers the series configuration of key areas of plant.

Additionally, simple parallel operation can be considered. This is fine for the basic “optioneering”, where the configuration is laid out, for example considering 1 oo 2, 2 oo 2, 2 oo 3, etc. trains for export, compression, power generation and so forth.

However, this can only reflect the basic equipment relationships and straightforward failures and could not replicate complex combinations of events, mitigating actions.

The simple spreadsheet approach can be OK for the coarse optioneering aspect as the simple availability results can be used when considering the impact of different configurations, trains, etc.

Different configurations will impact many factors, such as the cost, the weight (and therefore structural), power / heat / cooling requirements, the emissions, the layouts, etc., all of which are juggled during the early design phases to find a best fit concept. Any changes in the calculated availability can assist with arbitrating these options.

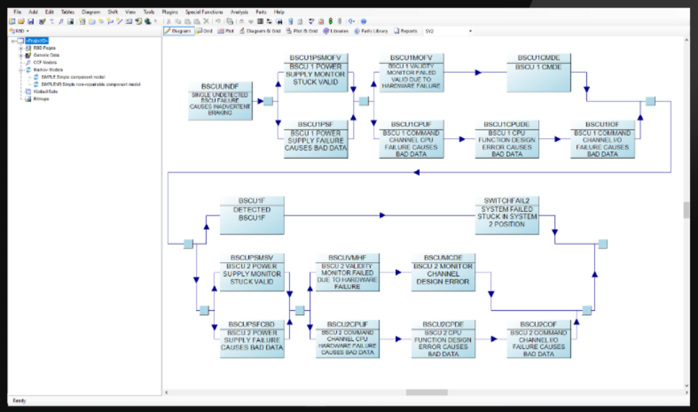

The more detailed RAM modelling uses simulation tools and should be carried out at the early stages to allow a deeper understanding of the design being progressed. It should be noted, that the basis for the model still relies on a series of RBDs, which contain elements representing the equipment.

The level of equipment modelled should be commensurate with the study objectives and the detail of the design stage. More simple representations of equipment can be later expanded to include further layers of detail as the design progresses and reflect differing strategies and characteristics of failure for equipment and on into components.

Primarily, the benefits of the model are that it simulates the behaviour of systems that are very difficult or impossible to study analytically, this is usually a “Monte Carlo” simulation program for the assessment of the availability characteristics of process, flow, and generative systems.

The Monte Carlo simulation is a computational algorithm that relies on repeated random sampling from user defined input data distributions to compute output parameters of interest.

This approach is used when the model is complex, nonlinear, infeasible, or impossible to compute an exact result with a deterministic algorithm, such as spreadsheets.

The benefits of this type of simulation are that it allows the operational capability of complex plants to be examined, including the interaction of many complicating factors, such as mitigating factors, queuing for repairs and spares, resource limitations, flaring constraints, buffer capacity, common mode failures, the effects of preventive maintenance, changes in plant configuration, changes in plant loading, etc.

It is simulated thousands of times to produce a distribution of the parameters of interest – usually availability or annualised throughput.

We are often asked how the RAM model can be constructed without any real-life data to populate it with.

The simple answer is that we do use representative data (or generic), which can be modified to suit local conditions, but what really counts is representing the relationships and the intervention times and logistic delay times, as these can far outweigh active repair times.

Even if nominal data is used, the model provides a valuable insight when the step changes in availability are considered and proves the robustness (or not) of the design to varying equipment performance.

When the base case RAM model has been validated and agreed to be representative, a series of sensitivities may be conducted aimed at investigating possible improvements to the Operational Availability or Production Efficiency of specific key production critical equipment/systems. Improvements which may readily be interrogated could include, for example:

- Updated reliability / performance data

- Equipment sparing changes to configuration / redundancy, particularly to mitigate single-point failures

- Use of modularisation and Plug n Play scenarios

- Equipment capacity changes

- Resource limitations, such as crew size, intervention time

- More rapid maintenance / logistics response.

Over the years we have conducted numerous RAM studies using a range of software tools.

Increasingly these days we see the use of the “simulation” Digital Twin approach, which provides a “situational awareness”, which is a term one of our partners uses.

The end result is the same, in that it allows the design function to consider operational scenarios, configurations, and limitations on throughput, spares, resources and so forth and thus provide an estimated through life costing across the whole operational lifecycle, which is after all what the operator should be interested in.

To sum up – A RAM model can provide enormous benefits when used in the early design stages and provide assurance that the design will remain effective throughout the whole lifecycle.

What we are really keen on, is that the RAM model should be passed on through all the design phases and into operations and continue to be used, such that the model becomes more than just a one-off analysis, but an operational management tool.

It can evolve throughout the lifecycle with refreshed data, revised configurations, revised process parameters and be used in decision making.

Typically, we would expect a RAM model to be revised every 1 to 2 years to ensure it stays aligned with current operations and that this is done throughout the asset lifecycle.

Although we started with the premise of conducting RAM modelling as early as possible: a good example of the through life model approach is in the late-life phase coming up to cessation of production, here with very high water cuts and reduced export the emphasis swings over to waste water handling.

The plant can become a water treatment facility with a side stream of produced oil. Aside from produced water throughput capacity limitations to be explored, the relationship between the impact of produced water equipment failure, redundancy, buffer capacities, etc. needs to be explored, and conversely the impact of reduced capacity or needs in export pumping can be explored.

Thus, the life of the RAM model is the life of the asset and it helps to feed into Asset Lifecycle Assessment and Strategic Asset Management Plan, Maintenance Budget Development and Obsolescence management.

Find out more about Optimal, here.

By Optimal

898 Views

Recent Posts

- Secerna Expands Life Sciences Team with the Addition of Trainee Patent Attorney

- Addison in ground breaking SAF development

- Flexitallic and TT Gaskets join forces to drive innovation within the New Energy sector

- Thermon: Enhancing Industrial Efficiency with Innovative Tubing Bundles

- Etc. For Business Newsletter – Winter Edition Now Live!

Back to News >