Clamp-on ultrasonic flowmeter technology is a breath of fresh air…

Non-invasive, clamp-on ultrasonic flow metering is proving to be a highly accurate measuring tool for high pressure oxygen in the petrochemical setting. Able to measure gases at temperatures over 100° C, ultrasonic technology uses sound waves to measure the flow of oxygen within the pipe. Alternating between transmitting and receiving pulses of ultrasound waves between two transducers, the flowmeter can accurately determine the flow rate.

FLEXIM was tasked with the retrofit of billing meters for oxygen at the world’s largest oxygen production site in Secunda, South Africa. A recent restructuring had meant that two companies would need to be able to bill each other for products and utilities across a common site, but there was no metering currently in place. The oxygen plant had previously been integrated within the chemical complex and was part of an internal system that previously required no metering.

Because of the large volumes traded, metering accuracy, reliability and repeatability were essential to both parties. A four channel meter was the solution, offering the best possible performance via non-intrusive measurement. The plant was large and complex, with numerous measuring points to be monitored, not least of which were the high temperature oxygen lines and headers, with temperatures ranging from 110 to 120° C. The pipes were over 40 years old, and despite having been insulated were showing their age, with signs of rust and corrosion on the surface.

Avoiding a costly shutdown.

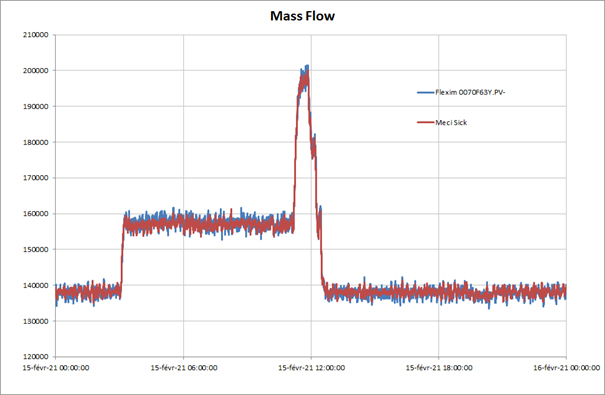

In order to install a traditional metering system, a factory shutdown would be needed. This simply wasn’t a feasible option, because of the associated high costs and long execution timing. So, to avoid this situation, it was agreed that a benchmarking test would be carried out to compare ultrasonic technology to a wetted multi-path custody transfer flowmeter installed on an Air Separation Unit. The tests were successfully undertaken and the commissioning was executed with no interruption whatsoever to the normal plant operations, in full compliance with safety and COVID-19 protocols.

The quad beam meter was permanently installed, in parallel with a custody system.

Chosen for its adaptability to both high and low temperature oxygen measurement, the quad beam meter also offers the benefit of increased accuracy thanks to the averaging of multiple sound paths, even where there are less than ideal inlet conditions. And because of the inbuilt flow computer, complexity and cost are reduced, with simultaneous reporting of both flow and diagnostic data achieved via the Modbus protocol. Special care had to be taken in making sure the specific grade of steel and resultant speed of sound was used, in order to achieve the maximum accuracy possible.

For more information on the benefits of non-invasive ultrasonic flow measurement of oxygen in the chemical industry, contact Simon Millington – www.flexim.co.uk | sales@flexim.co.uk | +44 (0)1606 781 420

External URL: https://www.flexim.co.uk

By FLEXIM Instruments UK Ltd

474 Views

Recent Posts

- Red flags in standard terms of business – tariff-related clauses and all

- Meet Conor Ryan, sustainability accounts manager at NEPIC

- Ten years apart, one shared award

- Process Industries Net Zero Centre for Doctoral Training – PINZ CDT

- Graham Hart Process Technology Joins Forces with Bradford University To Raise Funds and Awareness for the Teenage Cancer Trust

Back to News >