Choosing and Using Cables in Hazardous Areas

Selecting the best cable for your Hazardous Area Lighting application can be as important for safety as choosing the correct ATEX lighting equipment.

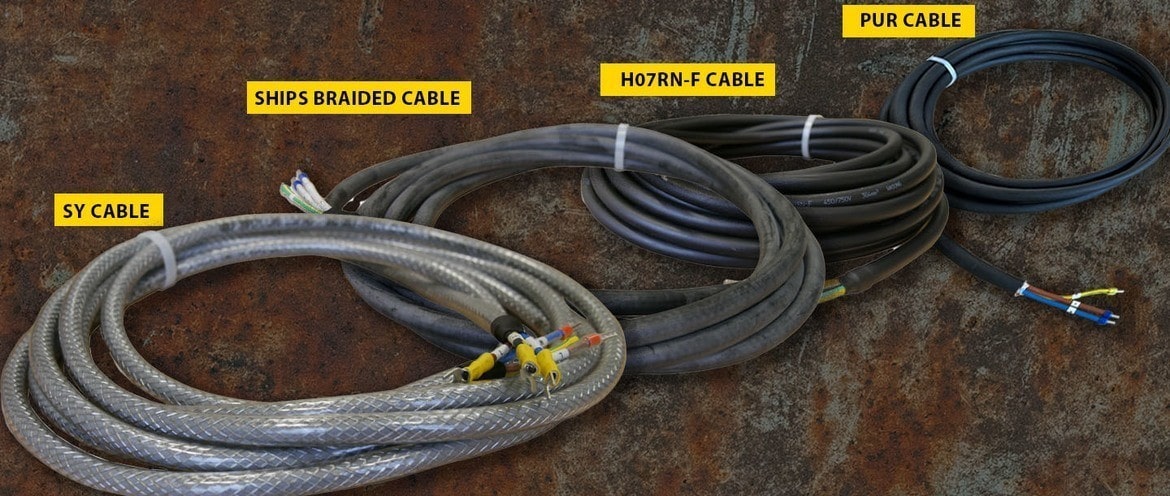

In this blog we look at six key issues that need to be considered and four of the most widely used cable types:

▪️ SY Cable

▪️ Ships Braided Cable

▪️ H07RN-F Cable

▪️ PUR Cables (which use Polyurethane as a sheathing material)

Thorne & Derrick distribute the complete range of Wolf portable & temporary lighting products including handlamps, torches, tank lighting and floodlights as well as ATEX cable reels to accommodate different applications.

CABLES FOR HAZARDOUS AREAS & EXPLOSIVE ATMOSPHERES

Having selected the most appropriate lighting for your environment and task, you should then consider the most suitable cabling, and the best way to manage it within the Hazardous Area.

For this, six key issues need to be taken into consideration:

• The ambient temperature of the work area

• The risk of mechanical damage to the cable in the work area

• Cable resistance to chemicals or solvents (usage dependent)

• Offshore specifications: low smoke, zero halogen

• Cable protection system 110/230V

• Length of cable run; particularly on 24 volt systems

Following the users’ assessment of these six points, the most appropriate cable can be chosen from the wide selection available, each of which has its own particular advantages.

The most widely used cable type in the on-shore energy and industrial sector is SY Cable.

SY CABLE

The SY cable has a PVC outer sheath and braided armour for protection against mechanical damage. The braided armour, also sometimes known as steel braid or mechanical protection, is particularly important when used in temporary applications where there’s a greater risk of it becoming trapped, walked on, or driven over. With a maximum high ambient temperature of +70 oC, this cable is ideal for hotter environments. However, it’s less suitable for low temperature environments below +5 oC, as the cable can become brittle.

SHIP’S BRAIDED CABLE

Often chosen for offshore installations and marine applications where a heat, oil and flame retardant cable is required. Like SY Cable, Ships Braided Cable contains steel braid, but is stronger and more robust, but less flexible. It’s compliant with BS6883, using low smoke, halogen free materials.

H07RN-F CABLE

Frequently used on Hazardous Area temporary lighting equipment in Europe. It’s a heavy-duty power supply cable with a tough rubber sheath, designed to be flexible and withstand chemical, mechanical and thermal stresses. It has a temperature rating of -30oC to +60oC for fixed installations (rising to +85oC for fixed protected installations) and from -15oC to +60oC when flexed.

PUR CABLES

More recent applications have been specifying cables which use Polyurethane as a sheathing material, often abbreviated to PUR cable. PUR cables are halogen free, flame resistant and offer increased mechanical, chemical, mud, and UV resistance – making PUR cables suitable for harsh environments. They can operate between -40oC and +125oC (individual cable technical specifications should always be referred to for precise upper and lower limits).

Not only should the user decide which cable best suits their needs, but also how to manage the cable in the work area. Care should be taken and it should be positioned to minimise the risk of cutting, abrading and damage from vehicles.

To increase safety further when using mains power in the Hazardous Area, users often use MCBs (Miniature Circuit Breakers – i.e., electronic fuses) or RCDs (Residual Current Devices). These reduce the risk of the cables overheating (if specified correctly) under fault current conditions, but it should be noted that these will not prevent the risk of a potentially explosive spark.

Low Voltage (24 Volt) applications present a number of additional issues to be taken into consideration. These include:

• The number of lights (which is determined by the VA rating of the transformer)

• The length of cable to be used (due to voltage drop over the cable length)

• The fuse value associated with protecting the cable run and ensuring the inductance of the cable does not reduce the fault current to the point the protective device would not operate

When using a 230/110V Input – 24V Output 400VA Transformer, the effectiveness of the fusing within the transformer is dependent upon cable resistance: cable resistance limits how much current can flow, so the longer the cable, the greater the resistance, which is especially relevant in Low Voltage applications where you only have 24V supply. Wolf offers the option of 42 volt transformers and products rated from 24-42 volts to substantially increase the cable runs.

Users looking to purchase an ATEX Transformer should ensure that information detailing the correct fuse value relative to the size and length of cable used is available to support safe and trouble-free usage in a Hazardous Area application. All Wolf transformers are supplied with supporting documentation detailing this data. Typically, the maximum cable length for 2.5sqmm core cable is 20m.

➡ See the full range of Wolf hazardous area ATEX Transformers used to provide safe and reliable temporary power distribution in hazardous area Zones 1 & 2 (Gas) and Zones 21 & 22 (Dust) with potentially explosive atmospheres.

PORTABLE & TEMPORARY HAZARDOUS AREA LIGHTING

When clear vision and brilliant LED light is required in hazardous area locations or confined spaces with potentially explosive atmospheres, Wolf Safety lights provide bold, bright and unfailing portable and temporary lighting. Since 1912, Wolf has been trusted to light the world’s most hazardous and hostile environments – with ATEX & IECEX certified portable lights to provide safe lighting in explosive atmospheres.

Thorne & Derrick are hazardous area lighting specialists stocking a complete range of portable and permanent fixed lighting including both fluorescent and LED technology in standard linear light fittings, wellglass, high bay and floodlight design certified by ATEX for both Zone 1 and Zone 2 hazardous areas.

External URL: https://www.heatingandprocess.com/choosing-and-using-cables-in-hazardous-areas/

By Thorne & Derrick International

1949 Views

Recent Posts

- Explore the Impact of Verifying Carbon Capture Technologies

- ITS wins Supplier of the Year at the ISPE UK Affiliate Annual Awards

- Cembre MG4 | The Newest Thermal Printer for Identification & Labelling | Available From Thorne & Derrick

- Share your expertise at ICPVT15: International Conference on Pressure Vessel Technology

- Minimising GWR Probe Build Up with the Magnetrol Eclipse 706

Back to News >