What does the ISCF Transforming the Foundation Industries (TFI) Challenge mean for the Chemicals Sector?

The foundation industries are worth approximately £45bn to the UK economy and employ 500,000 people. However, these sectors are the largest polluters generating 10% of all UK CO2 emissions. What can be done?

As the capital intensive nature of the industries can make it difficult to adopt new technologies and approaches, the Industrial Strategy Challenge Fund (ISCF) for Transforming the Foundation Industries (TFI) aims to enable these industries to improve productivity and/or resource and energy efficiencies while maintaining a competitive edge through:

accelerating innovation and new collaborations across sectors addressing sustainability

increasing multi/inter disciplinary research and innovation across sectors.

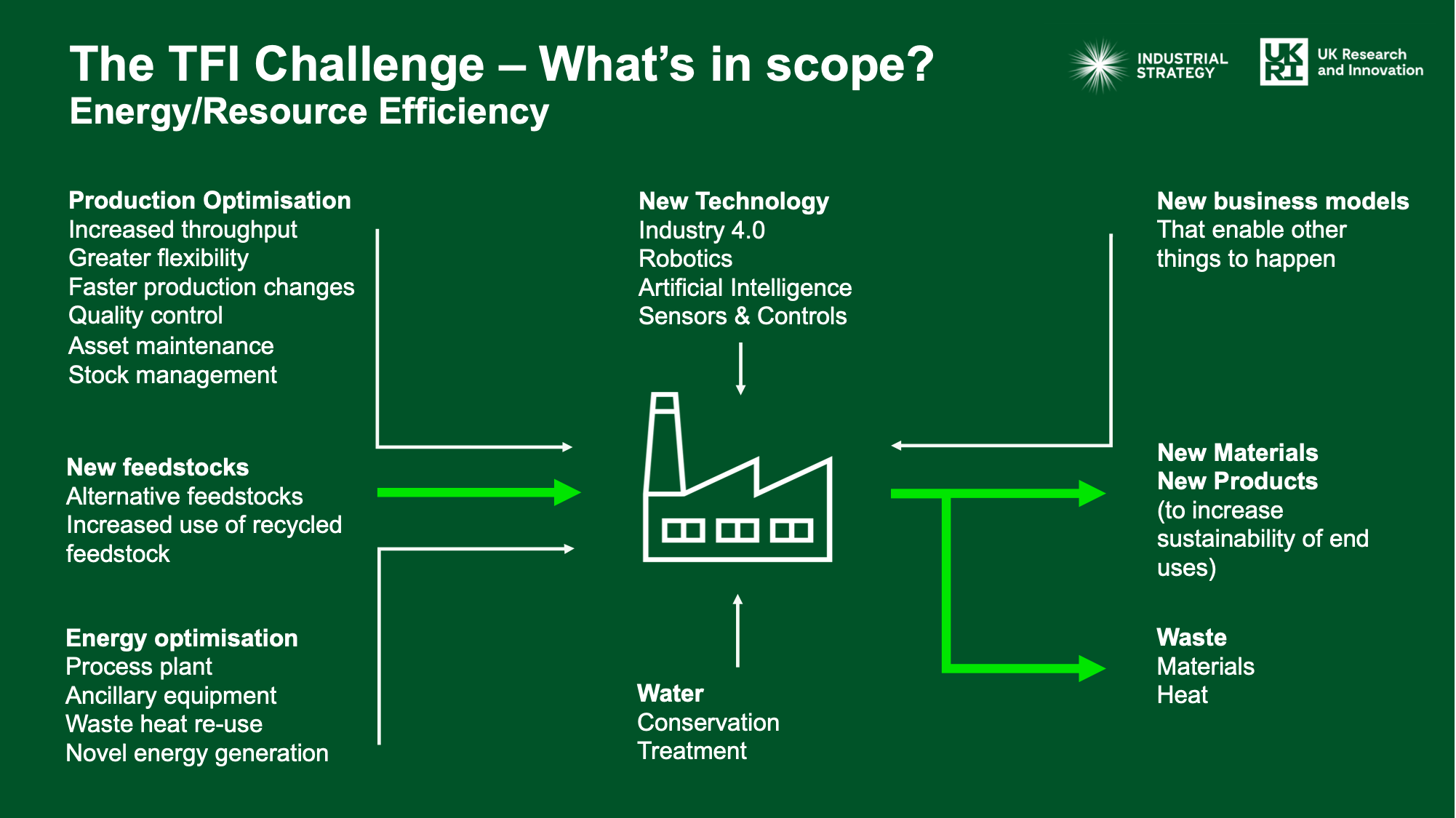

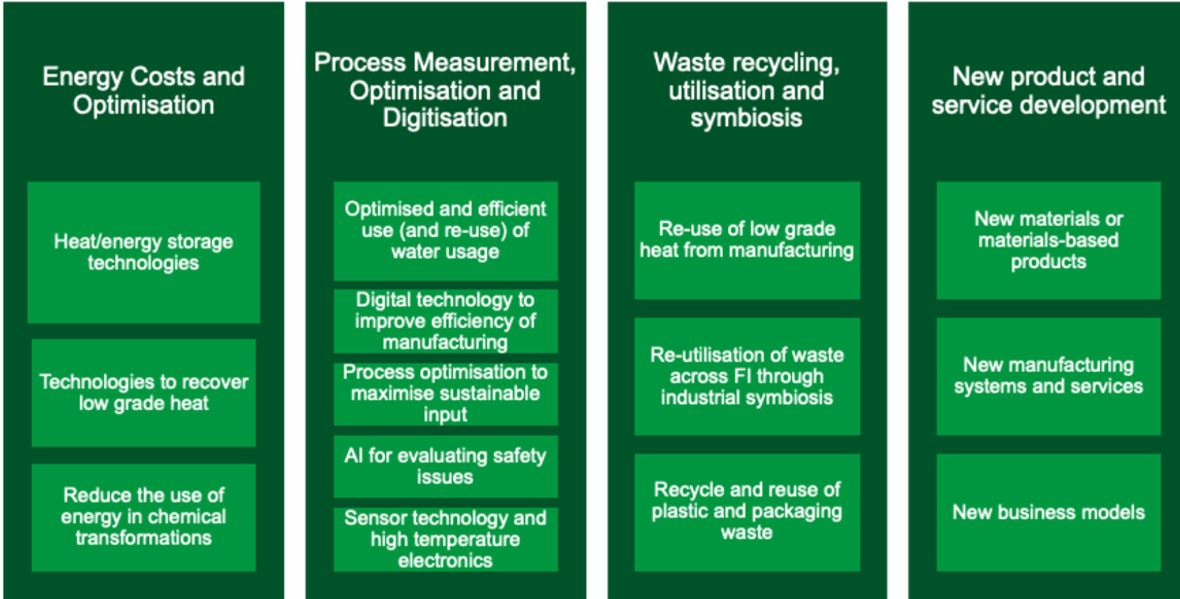

Priority areas and themes for the TFI challenge are shown in the graphic(s) below.

The chemical sector needs to continually innovate to makes step changes in sustainability whilst increasing productivity, resource and energy efficiency. It can do that through increasing throughput, reducing energy costs, waste valorisation, moving to alternative feedstock, process optimisation, low grade heat recovery and industrial symbiosis. All of these are priority areas under the TFI programme, which is why it should be attractive to the sector.

Below is a Q&A which aims to answer some key questions that you may have around the TFI Challenge.

Q. What are the foundation industries included in the ISCF TFI Challenge?

A. Includes Steel, Cement, Glass, Ceramics, Paper and Chemicals

Q. What Chemical industries are included?

A. Essentially all chemicals except oil refining and pharmaceuticals. However, if you have a project idea then scope enquiries can be submitted to support@innovateuk.ukri.org. Innovate UK will be happy to provide advice on scope prior to you committing to develop a full proposal.

Q. What are the cross-sector requirements of the competition?

A. TFI competitions require cross-sector collaboration between the foundation industries. The more collaborative the better and this can be through industrial symbiosis, for example, around alternative feedstock or waste, or even a shared technology. Collaboration with another foundation industry will be as a partner or through contribution-in-kind, but this isn’t always easy for the chemicals sector to achieve. As a minimum have a work package towards the end of the project that will require another foundation industry partner to evaluate or demonstrate the innovations benefits to their sectors manufacturing process. For example, another sector testing the specification, purity and performance of a new feedstock that has been produced from utilising CO2, waste or biomass.

Q. Do the chemical manufacturing processes have to be large or ‘mega’ tonne scale to be included?

A. No, processes don’t have to be large or ‘mega’ tonne scale. However projects need to focus on innovations that lead to step changes in productivity and/or resource efficiency that can demonstrate impact if deployed, especially where the transferable scale-out and scale-up opportunities can lead towards a larger accumulative benefit for the foundation industries. For example, an individual process utilising CO2 can be manufacturing product at small volumes, however the potential exploitation and deployment of new innovations across the UK could produce significant benefits

Q. Do companies need to be part of a cluster?

A. No, if the innovation development can be demonstrated to provide a step change increase in productivity or resource and energy efficiency then it doesn’t need to be part of a cluster. Also refer to the question above about scale of operation.

Q. Is Industrial Biotechnology and other enabling technologies out of scope?

A. Enabling technologies are in scope. Although any project needs to meet the scope and eligibility criteria, for example, be a cross-sector collaboration.

Q. Are alternative feedstocks within scope?

A. Yes, providing all other scope requirements are also met. Alternative feedstocks include the utilisation of CO2 and other ‘waste’ feedstocks. Note, projects focused solely on carbon capture for storage (rather than utilisation) is out of scope.

Q. Can you provide relevant examples of projects funded to date as part of the ISCF Transforming the Foundation industries competitions?

A. Yes. Results and public descriptions of projects winners for the ISCF Transforming Foundation Industries: Fast Start competition can be found on Innovate UK funding competition winners 2020 webpage. Within this document there a couple of useful examples of past applications that were in scope for TFI (please note: the proposals listed in the document have succeeded in the assessment stage of the competition but would have been subject to grant offer and conditions being met).

From the publicly available description, one application was for a project between the chemicals and paper industries looking at the production of a sustainable bio-based chemical, Levulinic acid (LA), by using aqueous streams from the paper industry. The LA could be used as a platform molecule leading to a green solvent or as a precursor for the production of advanced polymers, pharmaceuticals, additives and other commodity chemicals. The project would evaluate the scale-up and techno-economics of microwave assisted catalytic transformation of aqueous biomass containing streams into LA.

Another successful application was between the chemicals and glass industry. The project was to conduct a feasibility study looking at the low cost catalytic conversion of methane to high purity hydrogen for use as a supply to float glass manufacturing. The hydrogen is a by-product from functional carbon production and the project will produce a clean and usable hydrogen alongside high value and usable carbon products. This will enable industrial symbiosis between the foundation industries involved.

By NEPIC

630 Views

Recent Posts

- Explore the Impact of Verifying Carbon Capture Technologies

- ITS wins Supplier of the Year at the ISPE UK Affiliate Annual Awards

- Cembre MG4 | The Newest Thermal Printer for Identification & Labelling | Available From Thorne & Derrick

- Share your expertise at ICPVT15: International Conference on Pressure Vessel Technology

- Minimising GWR Probe Build Up with the Magnetrol Eclipse 706

Back to News >