Unilever, LanzaTech and India Glycols launch world’s first laundry capsule made from industrial carbon emissions

Credit: Bioenergy International

Global foodstuffs and consumer consumables major Unilever PLC has partnered with carbon recycler LanzaTech Inc., and India Glycols Ltd to produce a surfactant made from industrial carbon emissions instead of from fossil fuels.

The innovative shift in production utilizes biotechnologies and a newly configured supply chain between the three partners, who are working together for the first time.

Typically derived from fossil fuels, surfactants are a critical ingredient for creating the foam and cleaning action of many household cleaning and laundry products, from dish soaps to fabric detergents. The new process now allows surfactants to be made using recycled carbon.

Recycled carbon is a key form of renewable carbon and is essential to eliminating the use of fossil fuels. A recent report published by the Nova Institute and Unilever in April 2021 estimate that demand for fossil-derived chemicals will more than double by 2050.

Renewable carbon production will need to increase by a factor of 15 by 2050 to phase out the use of fossil carbon in consumer products. The process marks the first time a surfactant made using captured carbon emissions will come to market in a cleaning product.

However, why go through the trouble of managing all the details yourself when you can hire a reliable laundry service? Kleanway Laundry helps streamline your chores, offering convenience and quality without compromising. With professional care, your clothes stay fresh, clean, and well-maintained, saving you time and effort. Experience the ease of reclaiming your day while your laundry is expertly handled.

World Earth Day launch

The new surfactant will be used in an OMO (Persil) laundry capsule, which launched in China on April 22, World Earth Day. The product will come at no extra cost to consumers.

The product arrives to market as China continues to work towards its pledge of achieving net-zero carbon by 2060, and consumers increasingly seek out environmentally friendly products and practices.

Unilever consumer data from 2020 found that 87 percent of consumers in China considered climate change as serious a threat as the coronavirus (Covid-19), the highest of all countries polled. The breakthrough process involves primarily three stages:

- Capture: LanzaTech, a world leader in “CarbonSmart” products, uses biotechnology to capture waste industrial emissions at its Beijing Shougang LanzaTech plant in China and converts these emissions to ethanol;

- Conversion: India Glycols converts this ethanol into ethylene oxide, a key feedstock to make surfactants at their site in India;

- Formulation: Unilever uses the surfactant in the new OMO laundry capsules, manufactured at its Hefei factory in China.

Part of Unilever’s Clean Future strategy

The partnership is just one in a series of innovations Unilever is investing in as part of its Clean Future strategy, announced in September 2020. Under Clean Future, Unilever seeks to eliminate fossil-fuel-based chemicals from its cleaning and laundry product formulations by 2030.

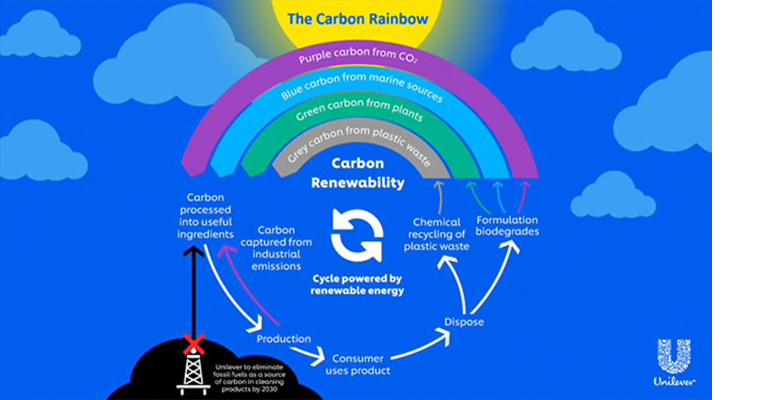

Central to Clean Future is Unilever’s ‘Carbon Rainbow’, a novel framework approach that diversifies sources of carbon used in product formulations.

Non-renewable fossil sources of carbon (identified in the Carbon Rainbow as black carbon) will be replaced using captured carbon dioxide (CO2) (purple carbon), plants and biological sources (green carbon), marine sources such as algae (blue carbon), and carbon recovered from waste materials (grey carbon).

Advancements in technology like this mean we can now reinvent the chemistry of our products. Instead of valuable carbon being released directly into the atmosphere, we can capture it and recycle it in our products instead of using fossil fuels We want to make sustainability easy for everyone that uses our products. New innovations like this help move our iconic cleaning brands away from fossil fuels without compromising on performance or affordability. We’re excited by the potential that this breakthrough represents for future innovations across our portfolio and our industry, said Peter ter Kulve, President Home Care, Unilever.

The OMO innovation is an example of ‘purple carbon’: carbon captured from industrial emissions.

At IGL, we have always been focusing on exploring novel ways to exploit renewable resources for making specialty products for our valued customers in different sectors. We are proud of being part of this consortium with Unilever and LanzaTech and creating the world’s first purple surfactant to launch in the market, said Uma Shankar Bhartia ji, Chairman and Managing Director, IGL

The process LanzaTech is using to create ethanol from captured carbon cuts the GHG emissions from this process by 82 percent compared to the traditional fossil-fuel process, according to a LanzaTech study.

Our planet is running out of time and how we treat carbon requires urgent revision. By working with Unilever and IGL we can turn waste carbon into an opportunity, keeping fossil fuels in the ground and enabling new circular processes to make the products we use every day, said Dr Jennifer Holmgren CEO, LanzaTech.

By NEPIC

1312 Views

Recent Posts

- The Crux of the Construction Challenge? Productivity, Sustainability, and Change

- Glacier Energy Delivers a 50 Metre Distillation Column

- IChemE Global Awards open for entries

- £20,000 Donation Boosts Mental Health Support for Veterans

- USA Tariffs Changes and how it impacts your business

Back to News >