MHT adds new Features on groundbreaking safety app CheckScheme

Health and safety on site have never been as important.

The storage and transportation of hazardous materials have many inherent risks.

Operators must follow strict safety procedures with accuracy and precision at all times.

If there is an accident because procedures were not followed, this could result in fines, injury and environmental damage.

We understand human error is inevitable, people are not robots, this is why we create our software and hardware to support digitalisation to boost safety and help overcome these challenges.

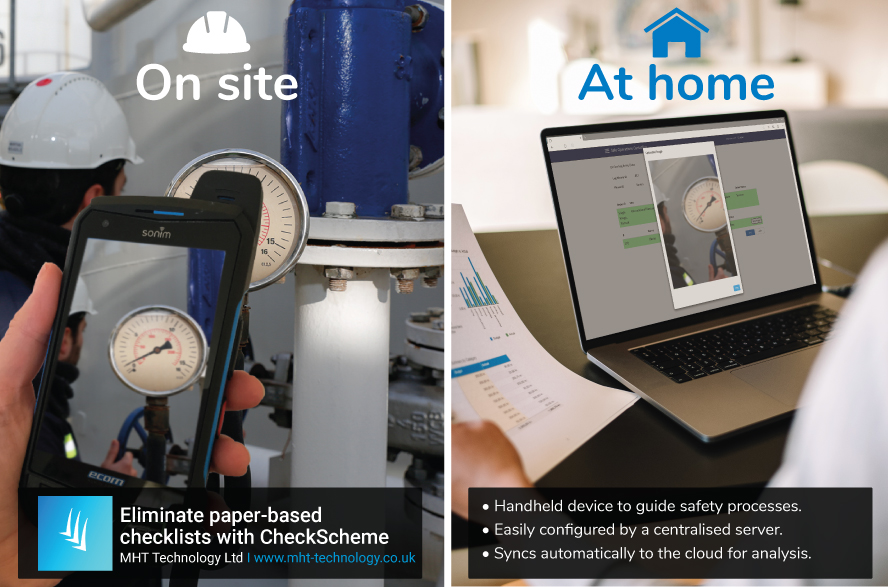

Our product, CheckScheme, enables operators to carry out their checks quickly and efficiently, harnessing existing data to optimise safety procedures with a user-friendly smartphone app.

We believe digitalisation is the key to helping our customers with the challenges faced at the moment. With CheckScheme managers can remotely monitor the processes being carried out by their colleagues on-site in a way that paper-based checklists simply could not.

The latest features in CheckScheme allow for the recording of richer data and scheduling repetitive tasks.

The system can still make use of RFID tags and QR Codes to identify locations and equipment, but now textual and photographic information can be recorded.

For example, CheckScheme users can record photographs of the laden vehicles before they leave the site, to be able to show that they have discharged their duties in line with ADR and ensure every vehicle with a hazardous load leaves your site carrying the correct placards and markers.

The built-in calendar allows processes to be scheduled.

Tasks such as manual tank dips can be scheduled to occur at regular intervals, capturing the levels recorded easily with the mobile device.

An RFID tag placed on the roof of the tank which the device reads ensure operators can’t falsify readings.

The server shows the results, permitting gauge drift to be assessed. See how CheckScheme can benefit your operations today.

By MHT Technology Ltd

560 Views

Recent Posts

- Explore the Impact of Verifying Carbon Capture Technologies

- ITS wins Supplier of the Year at the ISPE UK Affiliate Annual Awards

- Cembre MG4 | The Newest Thermal Printer for Identification & Labelling | Available From Thorne & Derrick

- Share your expertise at ICPVT15: International Conference on Pressure Vessel Technology

- Minimising GWR Probe Build Up with the Magnetrol Eclipse 706

Back to News >