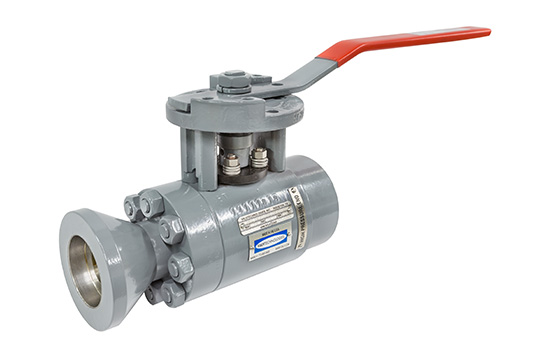

MCE Group Plc stocking Zero-Leakage Ball Valves

Many will know MCE Group Plc through our valve maintenance services, but did you also know we are stockists of the global leading V1-1 Metal-Seated Ball Valves manufactured by ValvTechnologies in Houston, Texas.

If you have High Temperature, High Pressure or Highly Abrasive applications, this is the product you should consider.

If you are using soft-seated valves on steam applications, you WILL be experiencing steam loss, and of course energy and money loss.

MCE can perform non-intrusive ValvPerformance Tests™ to ascertain leakage levels and outline the impact on plant efficiency in costs and emissions.

Payback on replacing soft-seated valves with V1-1 Ball Valves can be days, while also offering considerable longer term cost savings.

Sizes : 1/4 – 4″

Pressure Classes : ASME / ANSI Class 900 – 4500

End Connections : Socketweld, Buttweld, NPT, Flanged

Materials of Construction : Carbon steel (A105) / Alloy steel (F22, F91) / Stainless steel (316H) (Other materials available upon request)

In Compliance with : ASME B16.34 / PED / Nuclear ASME III Class 1, 2 and 3 / Nuclear Safety Related – 10CFR50 Appendix B / SIL

Shutoff : ABSOLUTE ZERO-LEAKAGE

By MCE Group Plc

870 Views

Recent Posts

- Nofirno Sealing System Successfully Tested for Use in Explosive Environments | CSD & Thorne & Derrick

- North East Children Challenging Industry Committee Meeting

- Cooperation vs True Collaboration in Construction – is the Industry Getting it all Wrong?

- Explore the Impact of Verifying Carbon Capture Technologies

- ITS wins Supplier of the Year at the ISPE UK Affiliate Annual Awards

Back to News >